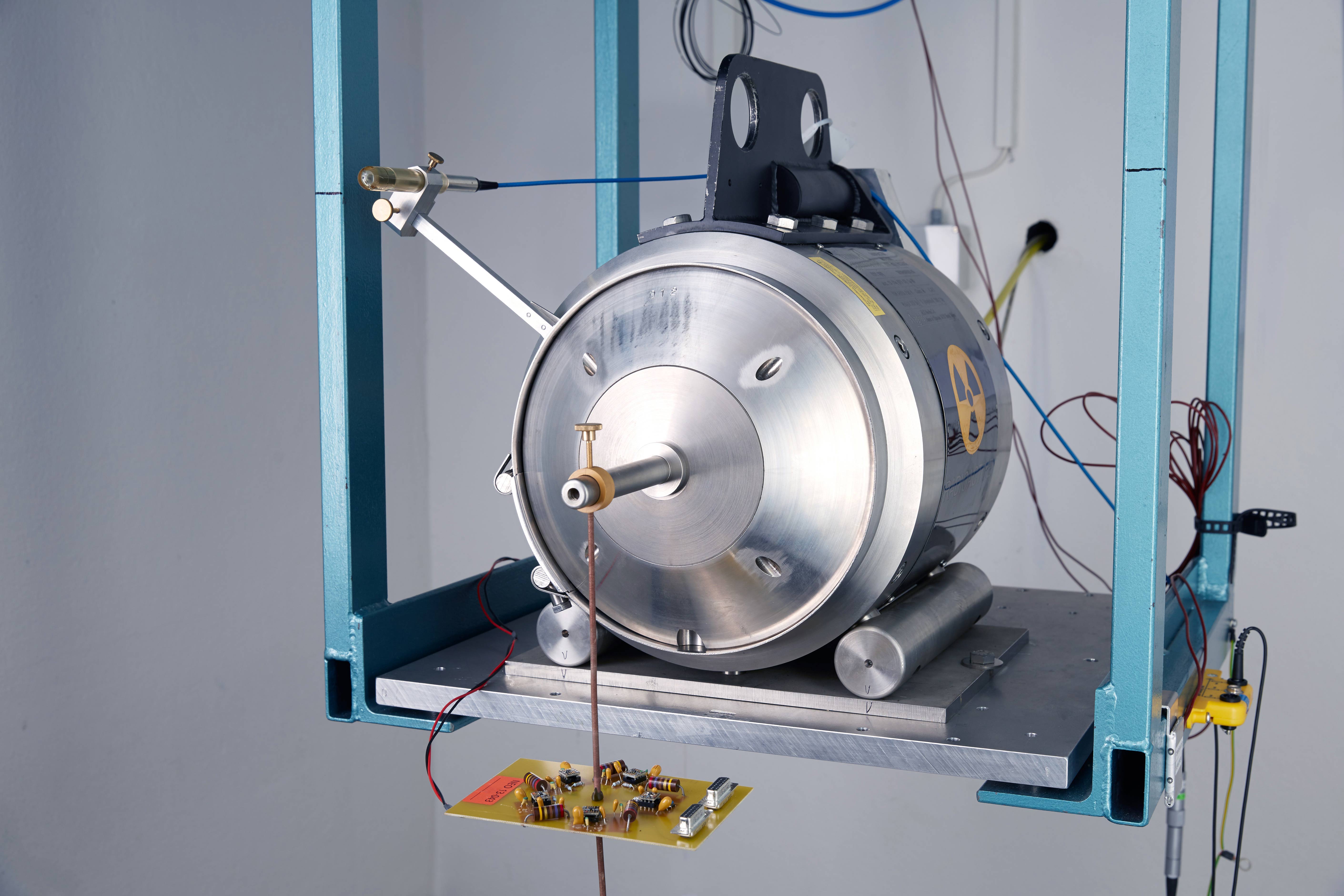

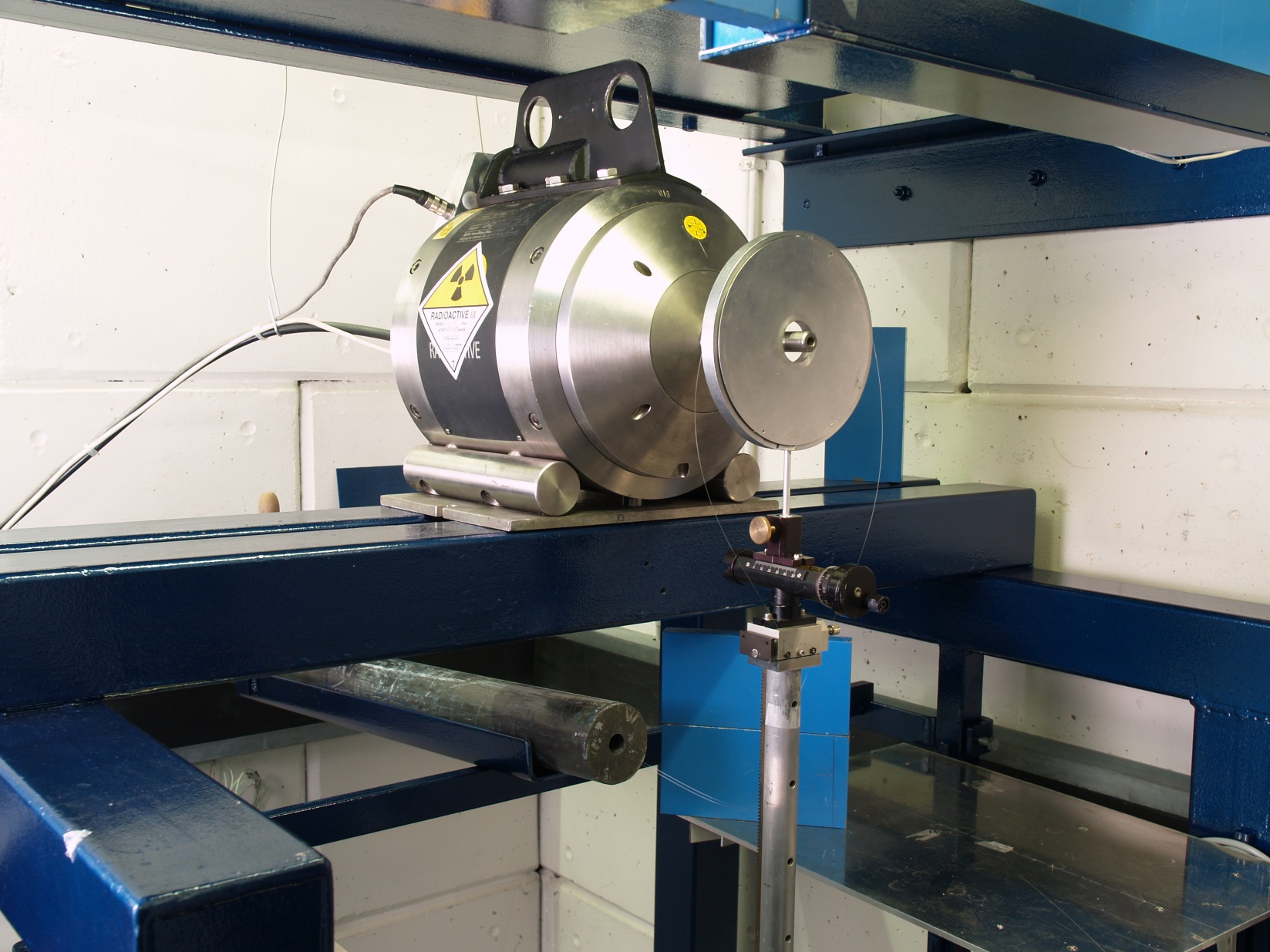

Co-60 Irradiation Facilities

Fraunhofer INT offers three in-house Co-60 facilities dedicated to irradiation testing of optical or electronic components or systems. The possible dose rates range from 10 μGy/s up to 2 Gy/s (corresponding to 3.6 rad/h up to 720 krad/h). One of these facilities is especially designed for low dose rate irradiations e.g. for ELDRS tests.

The applicable dose rate depends on the size of the irradiated objects as well as the targeted dose inhomogeneity in the objects. E.g. small samples can be irradiated up to 1 MGy (100 Mrad) in 5-6 days.

Infrastructure

Irradiations are possible both at low or elevated temperatures from -250 °C in a helium cryostat up to +150 °C. For very small samples temperatures up to +350 °C can be achieved.

It is possible to perform in-situ measurements on optical fibers or electronic components, i.e. over the period of the irradiation.

Electronic measurements prior to or after irradiation steps are performed in special ESD-safe laboratories and with professional high-grade equipment.

Technical details

Three Co-60 gamma irradiation facilities

Point geometry

Dose rates range from 10 μGy/s up to 2 Gy/s

Dedicated facility for low dose rate irradiations

Irradiations in the temperature range from -250 °C up to +150 °C

Dosimetry with calibrated ionization chambers and TLDs traceable to national standards

Option to perform in-situ/online measurements

Cobalt-60

Co-60 decays to Ni-60 via beta-decay with a half-life of 5.3 years. The excited Ni-60 nuclei decay to their ground state by emission of energetic gamma radiation with energies of 1.172 MeV and 1.332 MeV. As gamma radiation is highly penetrating, samples are irradiated fully and sample holders made of light materials (materials with low atomic numbers) have little effect on attenuating the radiation.

The radiation field is point-like and the homogeneity achievable during an irradiation therefor depends on the dimensions of the objects and the required or intended dose rate (Figure 6). With the irradiation facilities at INT, the dose rate ranges of all international standards are covered.

The dosimetry is determined regularly with calibrated dosimeters and ionization chambers manufactured by IBA and PTW and traced to national standards.

Irradiation options

The Co-60 facilities at Fraunhofer INT are designed for passive and active irradiations of electronic components and optical fibers. The available temperatures range from -250 °C to +150 °C (+350 °C for small samples).

Irradiations of full systems or custom setups are possible within the given test volume of 1 m3 at TK1000A or 4 m3 at TK1000B. The setups can be connected to equipment outside the irradiation area by fibers (ca. 20 m) or cables (TK1000A and TK100: 15 m, TK1000B: 10 m). Systems sensitive to temperature changes can be handled in a temperature stabilized and electromagnetically shielded measuring cabin at TK1000A or a measuring cabinet at TK1000B.

After irradiation the materials or devices are not themselves radioactive, so they can be handled or sent back to the customer right after the irradiation.

Consultancy and service

After irradiation, customers receive a detailed report with the relevant parameters (dose rate, dose, temperature and humidity during irradiation) and, if applicable, results of the measurements by INT.

Benefit from our consultancy and expertise prior to the irradiations to find the irradiation conditions best suited for your needs.

Fraunhofer Institute for Technological Trend Analysis INT

Fraunhofer Institute for Technological Trend Analysis INT