The aims of the QUANTOM® research project are to develop, build and test an innovative waste measurement system for the nondestructive material analysis and plausibility testing for radioactive waste contained in 200 l drums. The three partners, Framatome GmbH, AiNT GmbH and Fraunhofer INT, are collaborating in a project funded by the German Federal Ministry of Education and Research (BMBF) as part of the grant initiative “FORKA – Forschung zum Rückbau kerntechnischer Anlagen” (Research for the decommissioning of nuclear facilities).

Various activities produce radioactive waste. In the area of nuclear energy, waste is generated both in uranium processing and during the operation of the nuclear power plants themselves. Radioactive materials and sources are also used in medicine, industry and research. Due to the long half-lifes of several of the isotopes, the waste needs to be appropriately stored for a long period.

For low- and intermediate-level waste, the Konrad repository in Germany is to be available from 2027. The radioactive waste stored in Konrad must meet certain criteria. There are limitations regarding the activity inventory of radionuclides contained in the waste and also specific limit values for the non-radioactive components, for example, water pollutants like cadmium or arsenic.

Legacy waste currently often has an insufficient and inconsistent waste declaration compared to today’s standards, which prevents the qualification and final storage. Until now, the checking of radioactive waste for complete characteristics for final storage usually requires the laborious task of opening the waste packages, taking samples and to investigate the samples by laboratory analysis. These tests cause radiation exposure of the operating personnel. Moreover, after successful visual checks and sampling, the waste needs to be repackaged, which leads to an increase in waste volume. Furthermore, once the containers are opened, the legacy waste must be reclassified as new waste, and is thus subject to more restrictive requirements. In summary, destructive analysis leads to higher costs for final disposal.

Non-destructive assay avoids this disruptive testing of waste packages. Two established processes for this are the gross detection of neutrons and sectional gamma scanning. However, these can only provide information about the mass of fissile material and the radionuclide specific activity inventory contained, not about the non-radioactive elements or the corresponding material composition.

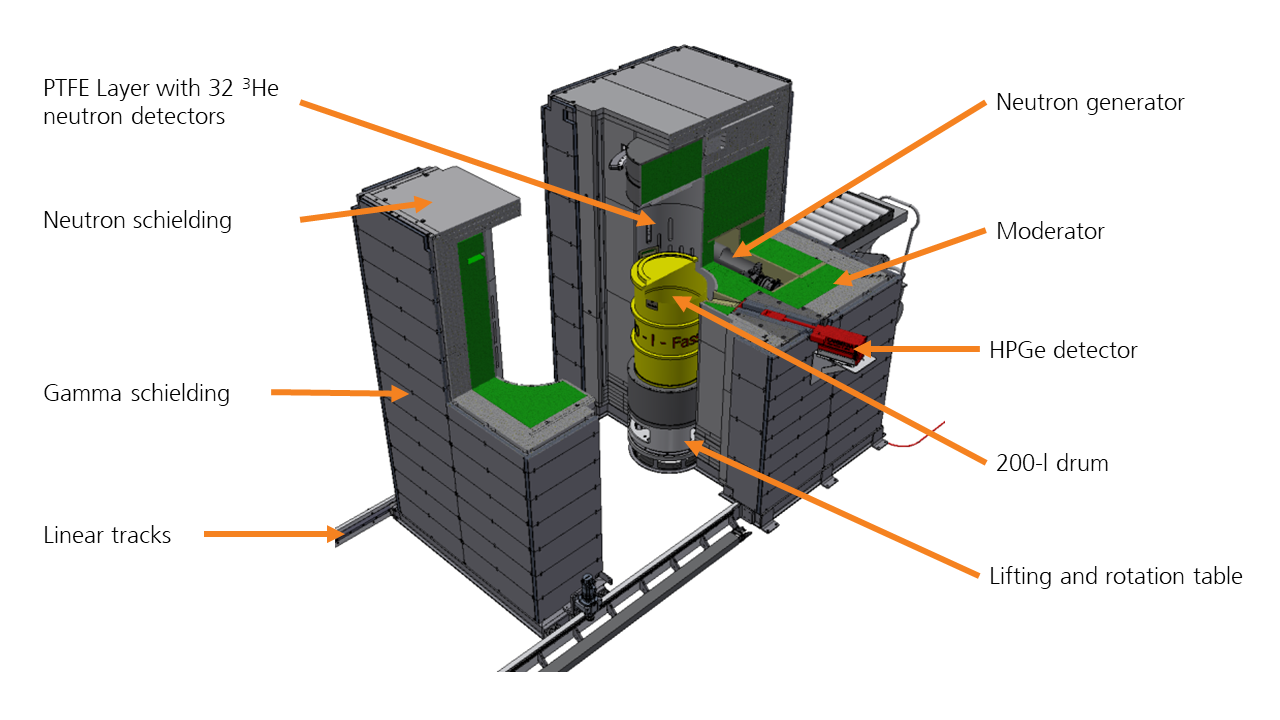

This is where the QUANTOM® project comes in. Prompt Gamma Neutron Activation Analysis is carried out for non-destructive analysis. In this process, fast neutrons with high penetration, are able to get inside the waste package. In a surrounding moderator (see Figure 1) and the waste matrix, the neutrons lose part of their energy and are then captured by the atomic nuclei of the packaged material. The atomic nuclei hereby emit characteristic gamma rays which act as a sort of fingerprint of the elements contained in the waste container. The gamma rays then penetrate to the outside and are detected there using a detector. This allows the identification of the elements in the waste package. From the intensity of the radiation, the amount of the respective element can be calculated, which thus allows the composition of the waste to be determined. The inspected drum is turned and lifted during the investigation, so that always a different section is measured. This determines the spatial distribution of elements in the container.

The system was under construction from 2019 in the technical centers of partner AiNT and was successfully completed in 2020. Framatome is responsible for procurement, mechanical construction of the system and the development of the system controls. The consortium partner AiNT develops the measuring and evaluation processes to be able to calculate the distribution of elements within the drum based on the measured data. Fraunhofer INT is responsible for measuring the neutron flux both at the source position and in the vicinity of the waste drum.

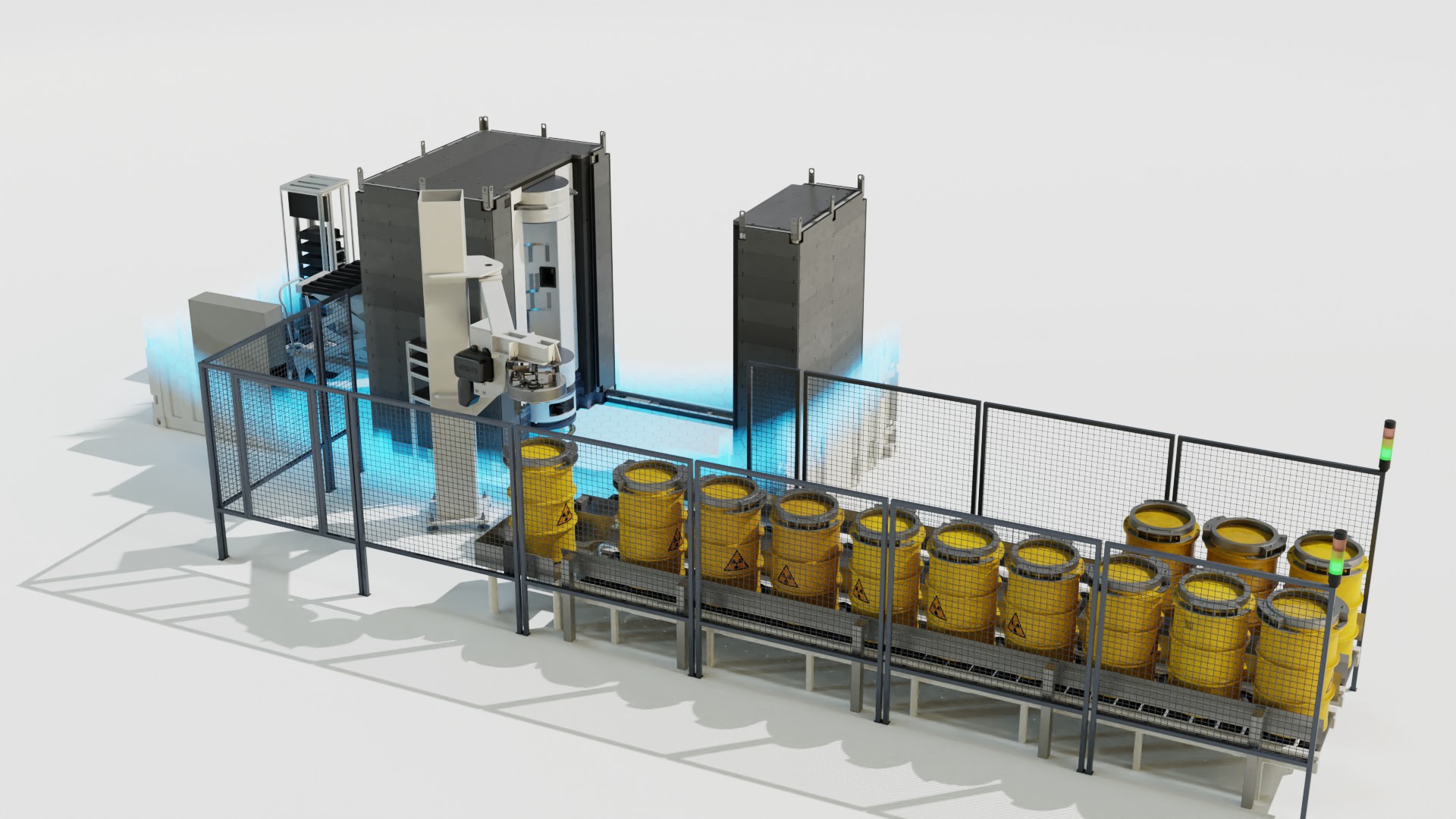

Figure 2 shows a view of the current planning state of the system. The drums enter the system via a conveyor belt. The crane collects a drum and sets it in the measuring chamber, where it is irradiated with neutrons. The container is surrounded by graphite in the measuring chamber which moderates the neutrons and improves the efficiency of the system. This chamber is closed for measuring. The drum is placed on a turning and lifting table in the chamber, which rotates to place different sections in front of the detector to be measured. In total there are two high-resolution gamma detectors (HPGe) to speed up the measuring process.

The neutron field inside the system is itself influenced by the contents of the waste matrix inside the drum, which has an effect on the measured results. Therefore, it is essential to know how the neutrons are distributed inside of the waste matrix in order to complete a qualitative analysis. AiNT is developing a software module for this purpose that calculates this distribution as part of the evaluation. Fraunhofer INT has developed and built a system for this purpose that measures the thermal neutron flux at 32 points around the container and also determines the source strength of the neutron generator with the help of a further neutron detector (fission chamber). Suitable components were selected for this purpose and the arrangement of the detectors was optimized for the purpose using Monte-Carlo N-Particle Transport Code simulations (MCNP is a program for simulating nuclear processes). The system was first put into operation at Fraunhofer INT and then integrated into the overall system at the AiNT technical center. The software control system for the neutron detectors was also realized at Fraunhofer INT. The validation of mass reconstruction algorithm and neutron flux detection has been successfully completed with non-radioactive packages.

In future, QUANTOM® will provide a system for the nondestructive analysis of waste packages without having to repackage them. This will significantly reduce the exposure of personnel to radiation and avoid an increase in waste volume. QUANTOM® is planned to be a mobile measuring system, integrated into a standard container. This enables the measuring system to be used wherever the waste is stored or conditioned, helping eliminate any unnecessary transportation of radioactive waste. The project is therefore making a significant contribution to the safer and more efficient disposal of radioactive waste.

The collaborative project QUANTOM® is financed by the German Federal Ministry of Education and Research, grant number 15S9406A / B / C. The project partners are responsible for the content of this publication

Fraunhofer Institute for Technological Trend Analysis INT

Fraunhofer Institute for Technological Trend Analysis INT