Overview

Radiation testing

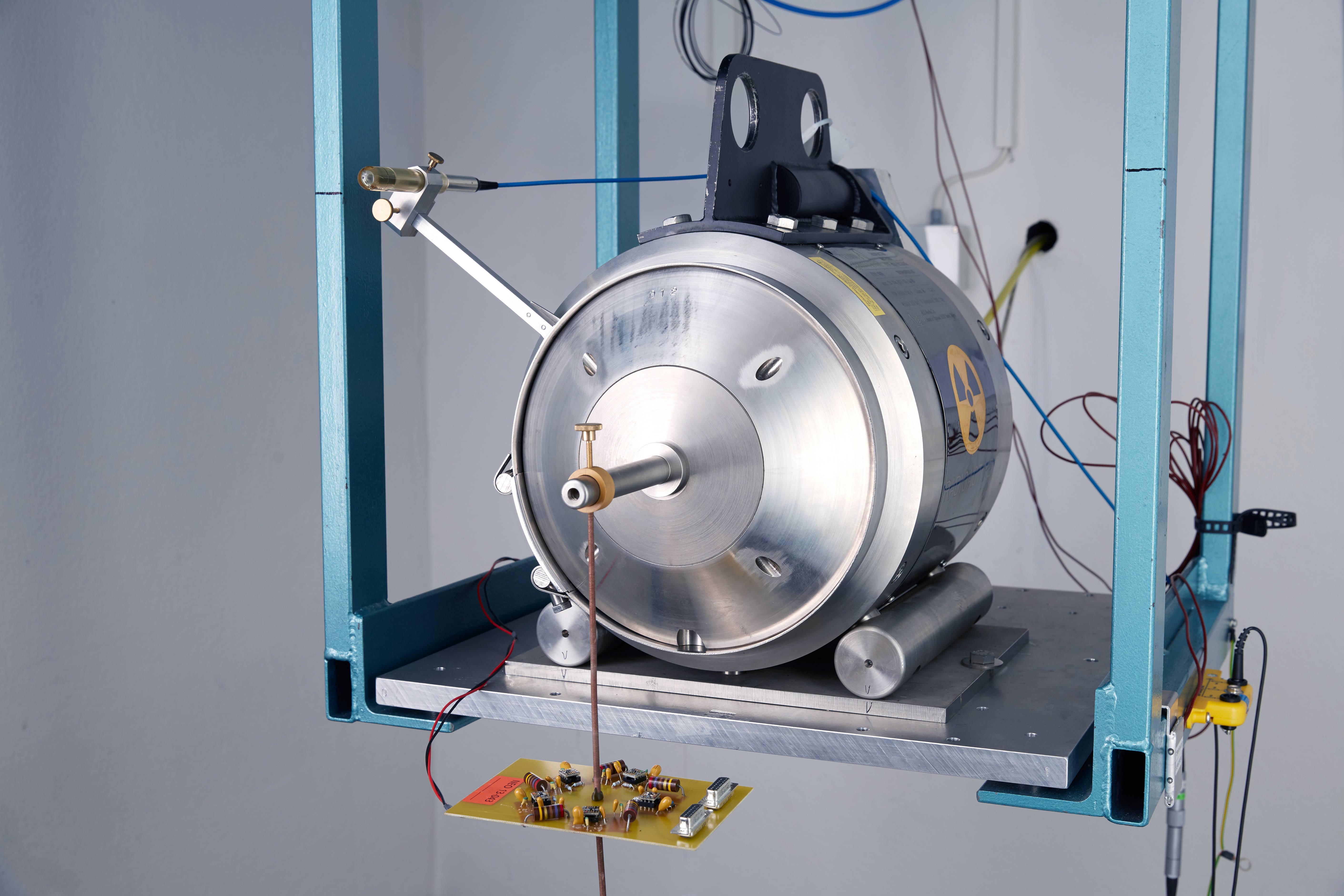

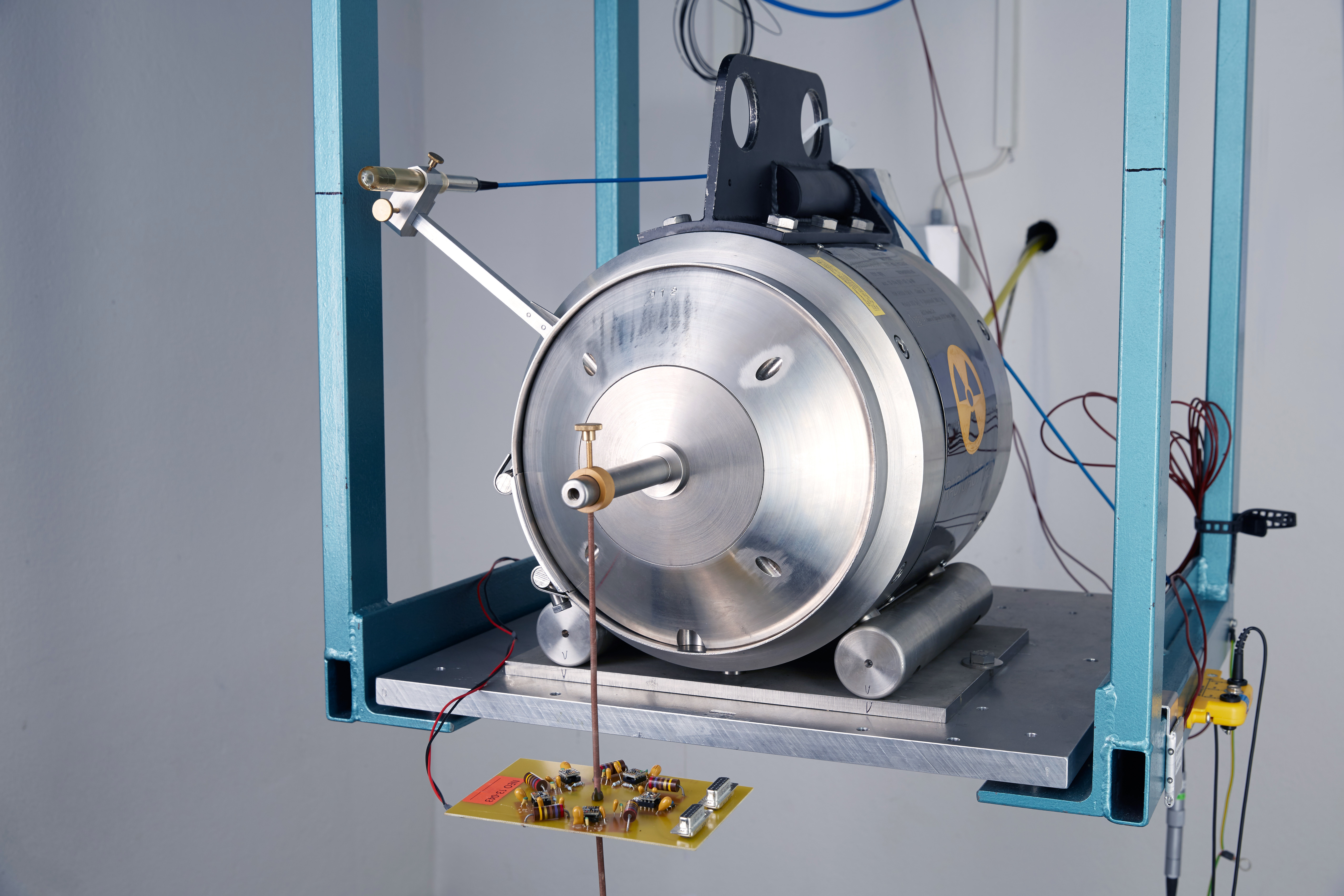

The business unit Nuclear Effects in Electronics and Optics (NEO) at Fraunhofer INT offers irradiation testing of electronic and optical parts or systems according to international standards (e.g. ESCC 22900) with high scientific accuracy. Three in-house Co-60 facilities and one 450 keV-X-ray facility dedicated to radiation testing are available at Fraunhofer INT.

Our services range from passive irradiations without additional measurements up to complex research programs. Tests can include step-stress or in-situ tests and parameter tests and under various conditions e.g. at high or low temperatures or in vacuum. Our experienced team can help you from the early planning phase of your experiment through the conduction of the tests until the interpretation of the results.

Since 2013, the business unit is ISO9001:2008 certified for the application and characterization of radiation effects in electronics and optics. We are constantly working on securing and improving the quality of our service.

Our range of services

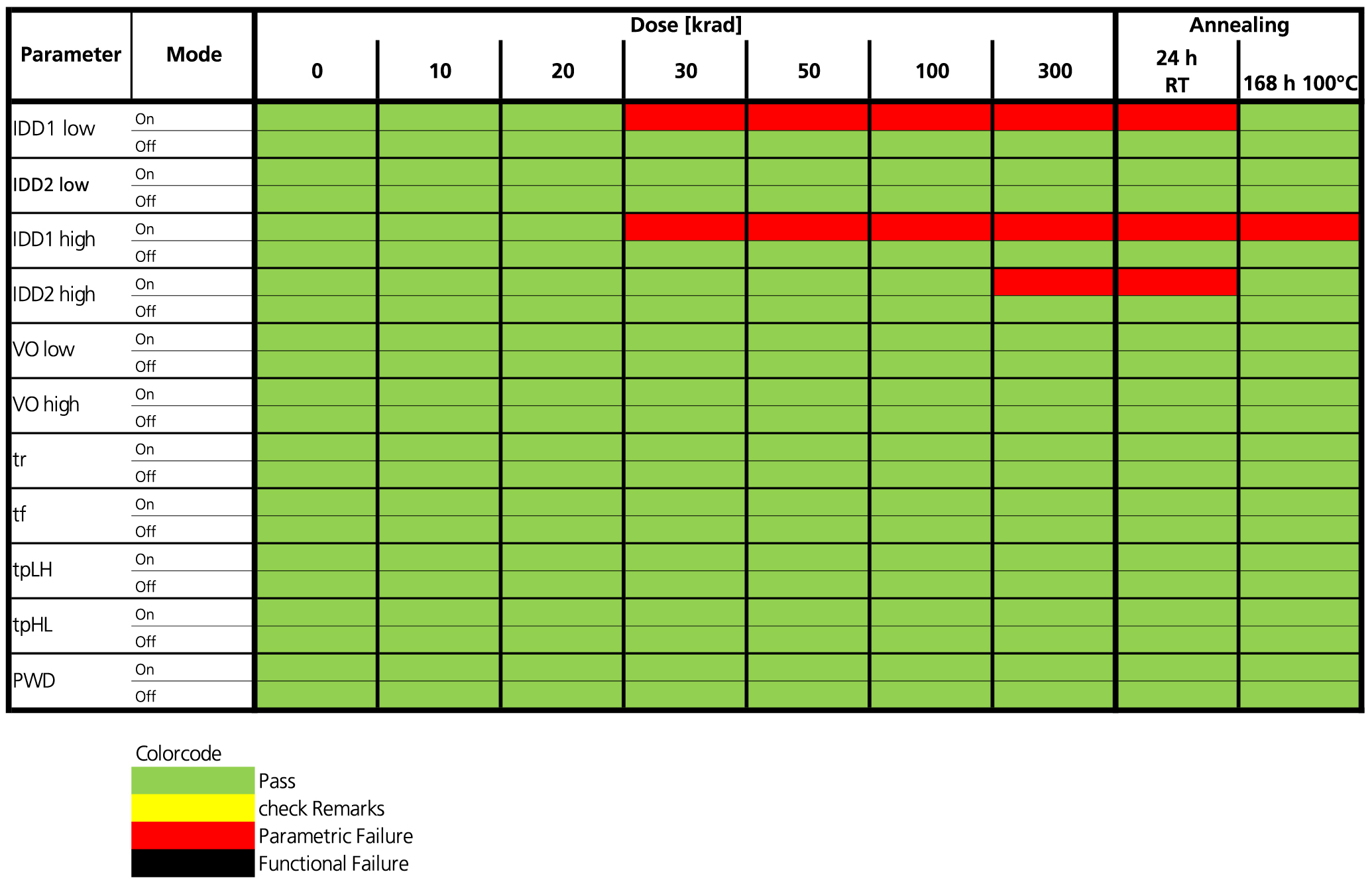

• TID tests according to international standards (e.g. ESCC 22900)

• ISO9001:2008 certified

• Support of your experiments with expert advice and execution from the early planning stages

• Three in-house Co-60 facilities with one dedicated setup for low dose rate and ELDRS tests

• In-house 450 keV X-Ray facility

• Active and passive tests on electrical or optical components or systems

• Large variety of radiation conditions (e.g. high and low temperatures, vacuum) accessible

Expertise in radiation testing

Effects of ionizing radiation are investigated by the business unit NEO for more than 40 years. In the last years NEO conducted more than 200 individual radiations tests on electronic or optical systems annually. These include qualification testing of electronic components as well as radiation testing of complete systems like sensors and control systems, laser systems and all types of optical fibers.

Our customer base includes both users and manufacturers of these devices with a focus on space and high energy accelerator applications. Several manufacturers of optical fibers rely on our testing expertise from development until market launch of new products. Since 2000 we successfully concluded over 300 projects for over 50 companies and 15 research facilities and published more than 50 peer reviewed scientific articles, and were involved in the development of several international standards e.g. IEC-60793-1-54, IEC-TR-62283, IEE-Std.-1682.

Furthermore, a biannual workshop on radiation effects specifically tailored towards the needs for small-to-medium sized companies or research institutions is organized and held by INT.

Accelerated testing

Electronic components exposed to harsh radiation environments e.g. during a satellite mission or next to an accelerator beamline, should be or have to be qualified for this scenario. The most basic test is the total ionizing dose (TID) test in which the expected total radiation dose is applied to the devices. To achieve reasonable running times of the experiments, this is done at significantly higher dose rates than present e.g. in space. This is called accelerated testing, which is suitable for most electronic components as no extra dose rate dependent effect will occur. Only some devices or device families show enhanced low dose rate sensitivity (ELDRS).

Fraunhofer INT offers three in-house Co-60-facilities and one 450 keV X-Ray facilities exclusively used by INT which are designed and optimized for radiation testing. Irradiations can be done in air or vacuum, at high or low temperatures or several other boundary conditions. For sensitive devices or equipment temperature-stabilized irradiations and measurements at room temperature are possible.

Test equipment

Fraunhofer INT is equipped with high grade experimental and laboratory equipment for testing of nearly all electrical and optical parameters. This equipment is regularly calibrated allowing measurement accuracies which can be reliably traced to national standards.

Standards compliant and ISO9001 certified

Since 2013, all services of the business unit NEO are ISO9001:2008 certified. NEO is the only radiation service provider with peer-reviewed processes regarding measurement accuracies for tests on optical fibers.

Unless desired otherwise by the customer, test procedures follow international standards like e.g. ESCC 22900.

Customized solutions and consulting

We, as a member of Europe largest research organization for applied sciences, have more to offer than standardized tests and qualifications. We can also help you with solutions customized to your needs. Benefit from our expertise in radiation environments, detector development and dosimetry.

Get in contact with us and see what solutions we can offer you!

Fraunhofer Institute for Technological Trend Analysis INT

Fraunhofer Institute for Technological Trend Analysis INT